产品推荐

RECOMMEND新闻推荐

NEWS RECOMMENDATION你知道济南C型钢的压轧工艺吗?

发布时间:2021-06-16 来源:http://www.jnhxtcg.com/

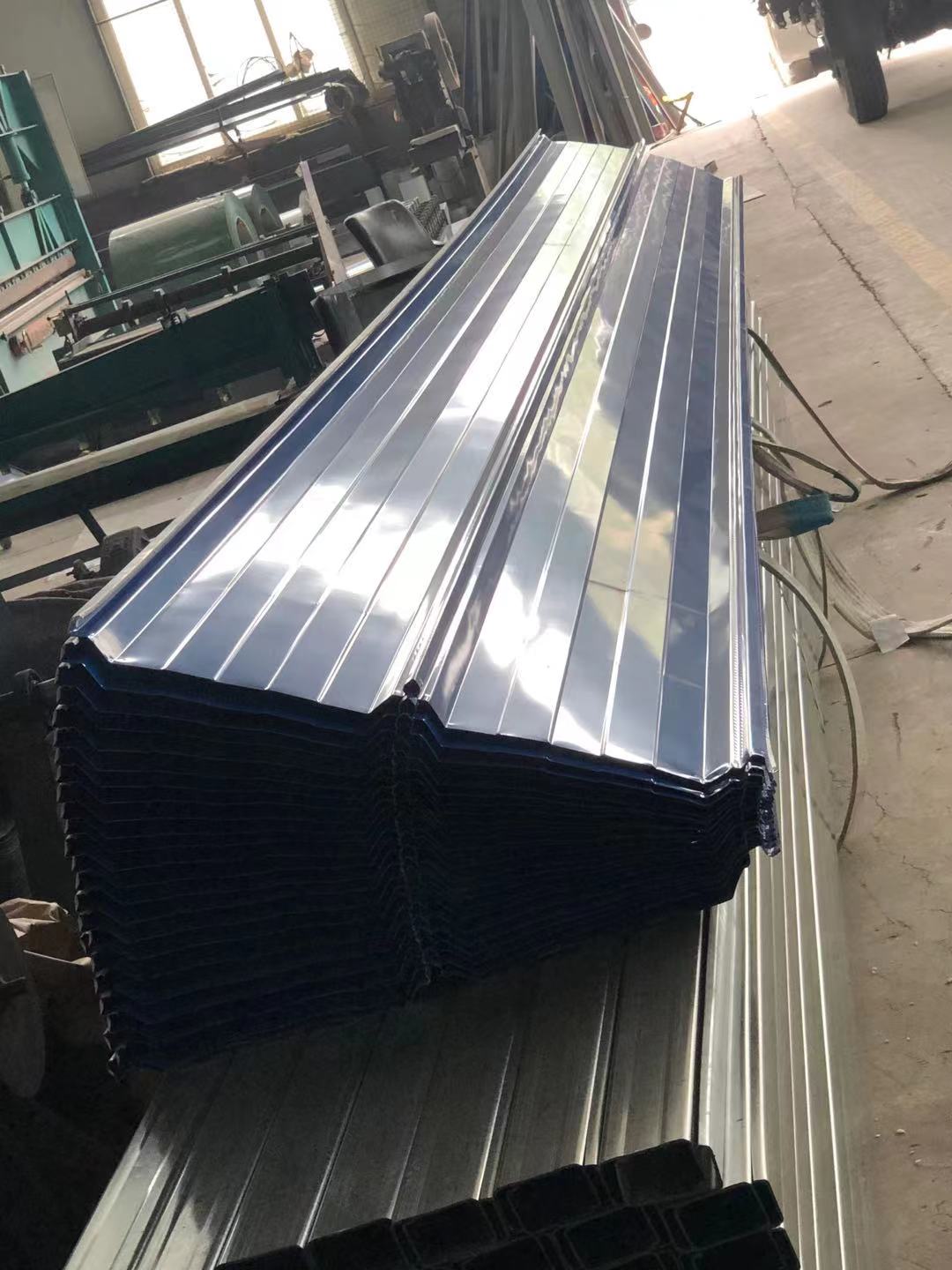

济南彩钢瓦c型钢对大家来说并不陌生。简单来说,就是一种看起来像英文字母中“C”的冷弯型钢,但又分为冷轧和热轧两种方式,这也是两种成型方式。此外,C型钢的成型方法也可分为:镀锌、热镀锌、冲孔等,那么大家知道济南C型钢的冷轧工艺吗?对此了解多少呢?接下来我们将为大家详细的总结一下。

Jinan color steel tile C steel is no stranger to everyone. In short, it is a kind of cold-formed section steel that looks like "C" in the English letter, but it can be divided into cold rolling and hot rolling, which are also two forming methods. In addition, the forming methods of C-beam can also be divided into: galvanizing, hot galvanizing, punching and so on. Do you know the cold rolling process of Jinan C-beam? How much do you know about this? Next, we will give you a detailed summary.

热轧和冷轧是型钢或钢板的成型工艺,对钢材的组织和性能有很大影响。钢材的轧制主要是热轧,冷轧只用于生产小断面钢和薄板。

Hot rolling and cold rolling are the forming processes of section steel or steel plate, which have great influence on the microstructure and properties of steel. Steel rolling is mainly hot rolling, cold rolling is only used for the production of small section steel and sheet.

冷轧C型钢是指在室温下进行冷弯、冷拉等一系列冷加工。这样形成的钢材虽然没有经过热塑压缩,但其截面上还是或多或少存在残余应力,会对C型钢的弯曲特性产生一定的影响。而热轧C型钢是热轧后内部分层的现象,大大削弱了抗拉能力,更严重的是可能出现层间撕裂,非常危险。而热轧C型钢也有残余应力,但这是由于冷却不均匀造成的残余应力。在外力的作用下,变形、稳定性、抗疲劳性都会出现问题,在一定程度上是危险的。

Cold rolled C-beam refers to a series of cold working such as cold bending and cold drawing at room temperature. Although the steel formed in this way has not been subjected to thermoplastic compression, there are more or less residual stresses in its section, which will have a certain impact on the bending characteristics of C-beam. The hot rolled C-beam is a phenomenon of internal delamination after hot rolling, which greatly weakens the tensile capacity. What's more, interlaminar tearing may occur, which is very dangerous. Hot rolled C-beam also has residual stress, which is caused by uneven cooling. Under the action of external force, deformation, stability, fatigue resistance will appear problems, to a certain extent, it is dangerous.

热轧可以破坏钢锭的铸造组织,细化钢的晶粒,消除显微组织缺陷,从而提高钢的致密力学性能。这种改善主要体现在轧制方向上,使钢材在一定程度上不再各向同性,在浇注过程中形成的气泡、裂纹、气孔也可以在高温高压下进行焊接。但是,冷轧具有成形速度快、成品率高、不损伤镀层的优点,可以制成各种截面形式,以满足使用条件的需要。冷轧能使钢产生很大的塑性变形,从而提高钢的屈服点。

Hot rolling can destroy the casting structure of ingot, refine the grain of steel, eliminate the microstructure defects, and improve the dense mechanical properties of steel. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent, and the bubbles, cracks and pores formed in the pouring process can also be welded under high temperature and high pressure. However, cold rolling has the advantages of fast forming speed, high yield and no damage to the coating. It can be made into various cross-section forms to meet the needs of service conditions. Cold rolling can cause great plastic deformation of steel, so as to improve the yield point of steel.

热门产品 / HOT PRODUCT